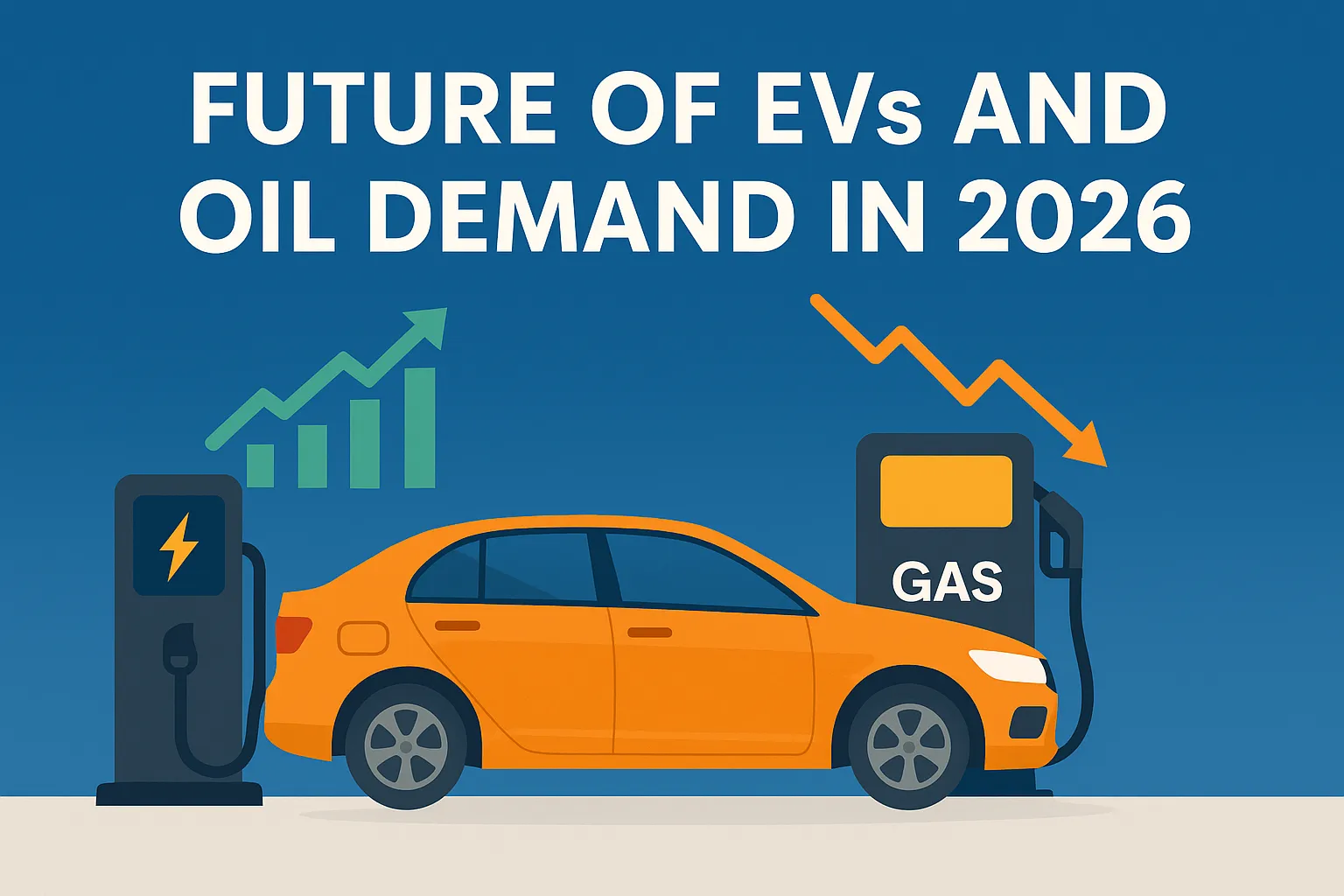

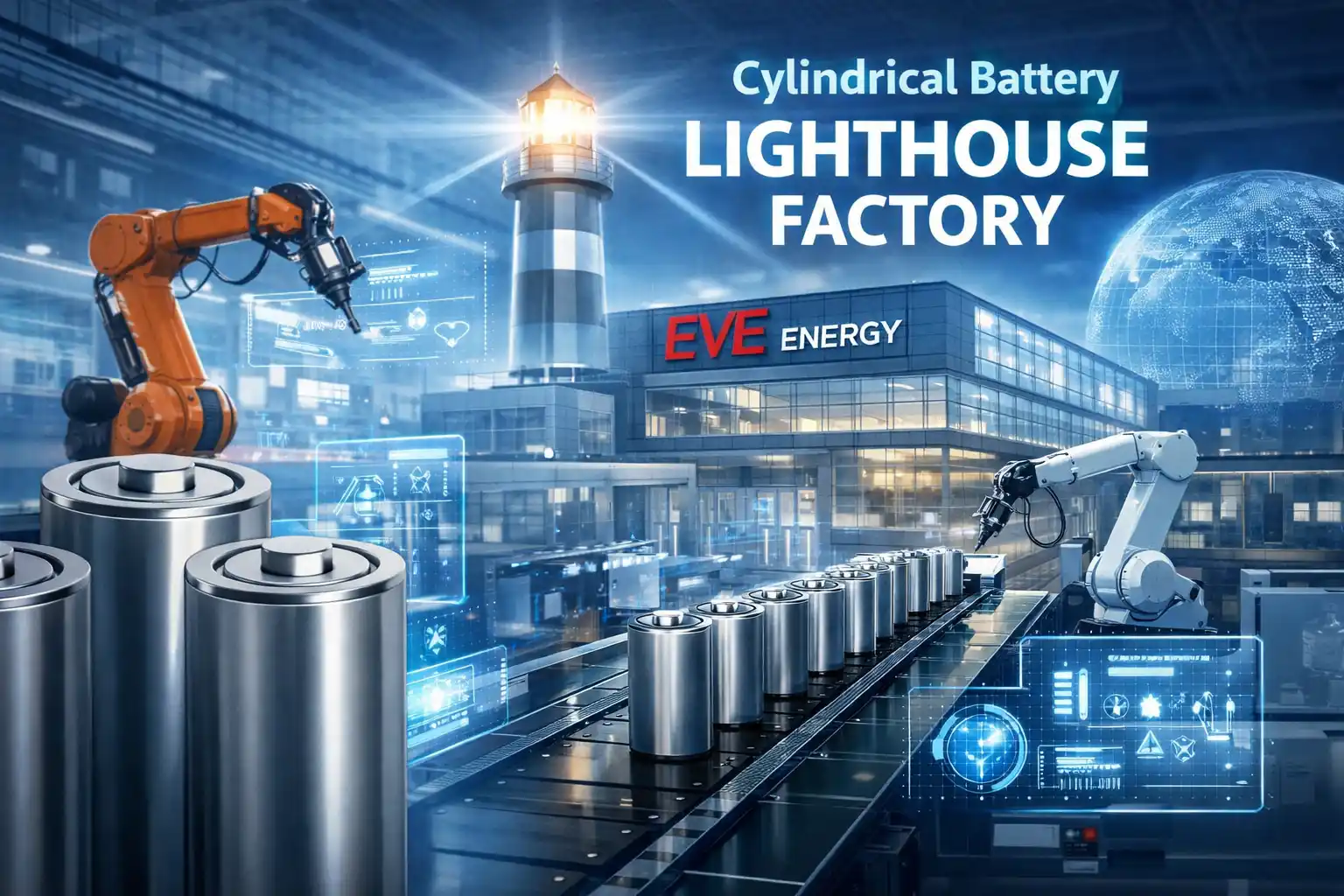

As the global electric vehicle (EV) and energy storage industries accelerate rapidly, battery manufacturing has become the backbone of the clean energy transition. In a landmark development, EVE Energy has achieved a historic milestone: its cylindrical battery manufacturing facility has been officially recognized by the World Economic Forum (WEF) as the world’s first “Cylindrical Battery Lighthouse Factory.”

This recognition is not just an award—it represents a fundamental shift in how next-generation batteries will be produced worldwide.

What Is a Lighthouse Factory? (Why This Matters)

The World Economic Forum’s Lighthouse Network identifies factories that successfully apply Fourth Industrial Revolution (Industry 4.0) technologies at scale.

To qualify, a factory must demonstrate real-world impact using:

- Artificial Intelligence (AI)

- Advanced robotics

- Big data analytics

- Internet of Things (IoT)

- Sustainable manufacturing practices

Until now, lighthouse factories were mainly seen in semiconductors, automotive, and electronics.

EVE Energy’s facility is the first ever lighthouse factory dedicated to cylindrical lithium-ion batteries, making this recognition globally significant.

Latest News: Why EVE Energy’s Factory Stands Out

The cylindrical battery factory in Jingmen, China, impressed WEF experts due to its ability to:

- Achieve ultra-high production speed

- Maintain consistent battery quality at scale

- Dramatically reduce energy use and carbon emissions

- Combine human expertise with AI-driven automation

This factory sets a new global benchmark for battery manufacturing efficiency and sustainability.

What Is a Cylindrical Battery?

A cylindrical battery is a round, tube-shaped battery—similar in shape to the AA or AAA batteries used in TV remotes.

The difference is:

- EV and industrial cylindrical batteries are larger

- They store much more energy

- They are designed for high power and long life

Why Not Rectangular Batteries?

Despite the availability of rectangular (prismatic) and pouch batteries, cylindrical batteries are widely preferred in large machines because they:

- Distribute heat more evenly

- Handle internal pressure better

- Reduce the risk of overheating and fire

- Offer higher consistency in mass production

This is why many EV manufacturers continue to rely on cylindrical battery designs.

About EVE Energy: Company Overview

EVE Energy Co., Ltd.

- Founded: 2001

- Headquarters: China

- Core focus: Lithium-ion battery technology

EVE Energy supplies batteries for:

- Electric vehicles (EVs)

- Energy storage systems

- Power tools

- Industrial and smart equipment

Over the years, the company has become a key global supplier of cylindrical batteries, serving both domestic and international markets.

Inside the World’s First Cylindrical Battery Lighthouse Factory

1. Ultra-High-Speed Production Lines

- Each production line can manufacture around 300 battery cells per minute

- Annual output reaches hundreds of millions of cells

- Real-time monitoring minimizes downtime

Industry Impact:

High-speed automation significantly reduces battery costs, making EVs more affordable.

2. AI-Driven Smart Manufacturing

- Every machine is connected through AI systems

- AI predicts:

- Equipment failures

- Quality deviations

- Maintenance is preventive, not reactive

Result:

Lower production losses and near-zero unplanned shutdowns.

3. Advanced Quality Control

- AI-powered vision systems inspect every cell

- Inspection time: ~0.3 seconds per battery

- First-pass quality yield exceeds 97%

Meaning:

Most batteries pass quality checks on the first attempt, ensuring high reliability.

4. Sustainable and Green Manufacturing

- Energy consumption per battery reduced by over 50%

- Carbon emissions cut by nearly 60%

- Integrated waste reduction and recycling systems

Each battery is also assigned a Digital Battery Passport, allowing:

- Full lifecycle tracking

- Easier recycling and reuse in the future

5. Human–Machine Collaboration

- Workers use AR-based digital training tools

- Smart sensors monitor workplace safety

- Automation enhances skills rather than replacing jobs

This approach creates a future-ready workforce alongside smart machines.

Why Cylindrical Batteries Are Ideal for EVs and Large Machines

| Key Factor | Advantage |

| Heat management | Uniform cooling and lower thermal risk |

| Structural strength | Cylinder shape resists internal pressure |

| Safety | Lower chance of thermal runaway |

| Cost efficiency | Optimized for mass production |

| Scalability | Same design, multiple sizes |

These advantages make cylindrical batteries especially suitable for EVs, energy storage, and heavy industrial applications.

Global Impact: What Changes Next?

Electric Vehicles

- Lower battery costs

- Faster EV adoption

- Improved safety standards

Manufacturing Industry

- AI-powered factories become the new standard

- Traditional plants face competitive pressure

Environmental Impact

- Cleaner battery production

- Stronger push toward sustainable energy systems

Expert Insight

“EVE Energy’s lighthouse factory proves that speed, quality, and sustainability can scale together.

This model represents the future of battery manufacturing worldwide.”

Final Conclusion

EVE Energy’s Cylindrical Battery Lighthouse Factory is more than a technological achievement—it is a blueprint for the future of global battery manufacturing.

By combining AI, automation, sustainability, and human expertise, the company has demonstrated how batteries can be produced:

- Faster

- Safer

- More efficiently

- With a lower environmental footprint

As EV adoption accelerates worldwide, this manufacturing model is likely to shape the next decade of the battery industry.

Source: prnewswire , wef