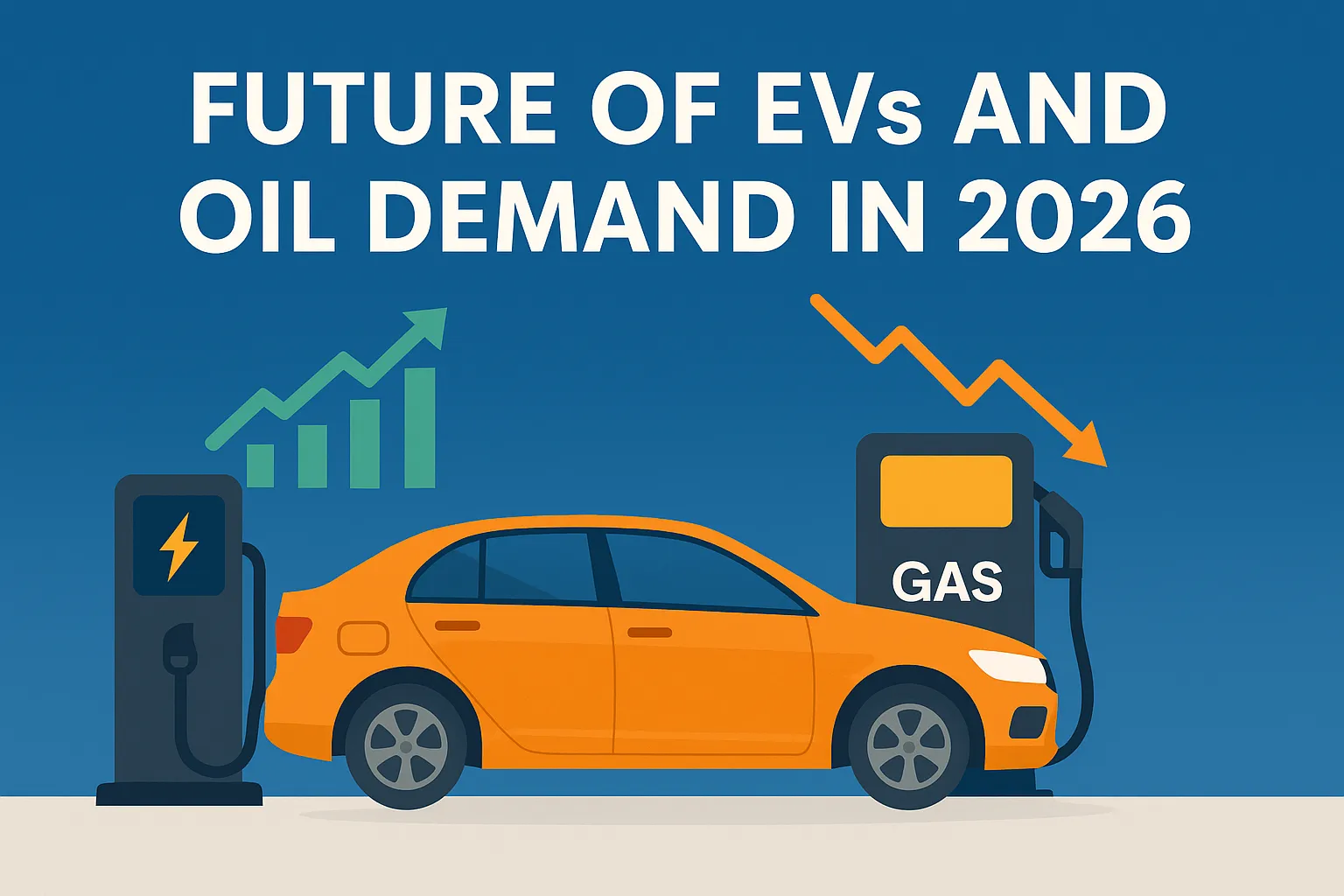

The world is rapidly shifting toward Electric Vehicles (EVs), renewable energy, and large-scale battery storage. While this transition is great for reducing pollution and fossil fuel use, it also brings a new challenge — what happens to millions of batteries after they reach the end of their life?

An EV battery typically lasts 6–10 years. In the coming decade, a massive number of batteries will need replacement. If disposed of improperly, they can harm the environment.

This is where Battery Recycling and the Circular Economy emerge as a powerful solution — turning battery waste into valuable resources again.

Let’s understand this technology in detail.

What Is Circular Economy?

Traditionally, industries follow a linear economy model:

Mine raw materials → manufacture products → use → discard

Circular Economy changes this model to:

Use → recycle → reuse

In the battery industry, this means extracting valuable metals from used batteries and using them again to produce new batteries.

This approach:

- Reduces mining dependency

- Cuts waste

- Conserves resources

- Potentially lowers battery costs

What’s New in Battery Recycling Today?

Batteries have been recycled before, so why is this topic suddenly important?

The difference now lies in scale and technology.

1) EV Adoption Is Creating a Battery Wave

Earlier, recycling focused mostly on small batteries or lead-acid car batteries. Now, EV adoption is exploding worldwide, and millions of large lithium batteries will reach end-of-life in the next decade.

2) Advanced Recycling Technologies

Modern recycling processes can now recover lithium, nickel, and cobalt in high purity, making them suitable for new battery production.

Earlier methods recovered less material and were less efficient.

3) Recycling Is Becoming a Profitable Industry

Battery metals are becoming expensive and strategically important. Recycling is no longer just environmental management — it is becoming a major business opportunity.

How Does Battery Recycling Work? (Step-by-Step)

1) Battery Collection

Used EV and electronics batteries are collected and transported safely since damaged batteries can be hazardous.

2) Battery Disassembly

Batteries are discharged and dismantled safely into components.

3) Mechanical Processing

Batteries are shredded, and materials like plastic, aluminum, and copper are separated.

4) Chemical Metal Extraction

Advanced chemical processes recover lithium, cobalt, and nickel.

5) New Battery Production

Recovered materials are reused to manufacture new batteries, restarting the battery lifecycle.

Companies Leading Battery Recycling Innovation

Several companies are heavily investing in battery recycling as a future growth sector:

- Redwood Materials — Focused on recovering battery materials and feeding them back into the EV supply chain.

- Li-Cycle — Developing large-scale lithium-ion battery recycling facilities.

- CATL — The world’s largest battery manufacturer, also building battery recycling ecosystems.

Many automakers are also developing their own recycling networks to secure material supply.

Key Benefits of Battery Recycling

✅ Environmental Protection

Reduces hazardous battery waste and pollution.

✅ Less Mining Required

Reduces the need to extract new raw materials from the earth.

✅ Potentially Lower Battery Costs

Recycled materials can lower production costs over time.

✅ Improved Energy Security

Countries can reduce dependence on imported raw materials.

✅ New Industry & Job Creation

Recycling plants, logistics, and processing industries will create employment opportunities.

⚠️ Challenges Still Exist

Despite rapid progress, challenges remain:

- Recycling processes are still expensive

- Battery designs vary across manufacturers

- Collection systems are not fully developed globally

- Handling damaged batteries safely is complex

However, ongoing investments and research are steadily improving these areas.

When Will Battery Recycling Become Mainstream?

Industry trends suggest:

- 2026–2030: Rapid expansion of recycling facilities

- Early 2030s: Large volumes of EV batteries enter recycling streams

- By 2035: Recycling becomes a key pillar of battery supply chains

The next decade will be critical for this industry.

What Could the Future Look Like?

In the future:

- Most EV batteries may be recycled into new ones

- Mining dependency could significantly decrease

- Battery waste may drastically reduce

- Clean energy adoption could accelerate

Battery manufacturing may shift from a waste-generating industry to a circular ecosystem.

Final Thought — Turning Waste Into Opportunity

Every technological revolution brings new challenges. The EV revolution is no different.

But Battery Recycling and Circular Economy show that with innovation and planning, challenges can be transformed into opportunities.

The smartest future technologies will not only create new products but also reuse resources wisely.

Battery recycling may not be the most talked-about sector today, but in the coming years, it could become one of the most important industries shaping our energy and environmental future.

The real revolution lies in turning waste into value.